![]() Pennsylvania Railroad FD-2/FW-1 Project Update

Pennsylvania Railroad FD-2/FW-1 Project Update

![]()

All information and images protected, Copyright © 1997- 2023 Kohs & Company Inc, All Rights Reserved |

Availability: Both FD and FW versions of this project are available for immediate delivery as shown below. If you are interested in receiving further information or are interested in a version not listed, please get in touch using my contact information. The project literature is also available from the project Download page.

Model Version Currently Available: 2, 5 & 6 Price: $1,500USD + Load Versions Produced: 6 Production Quantity: 125

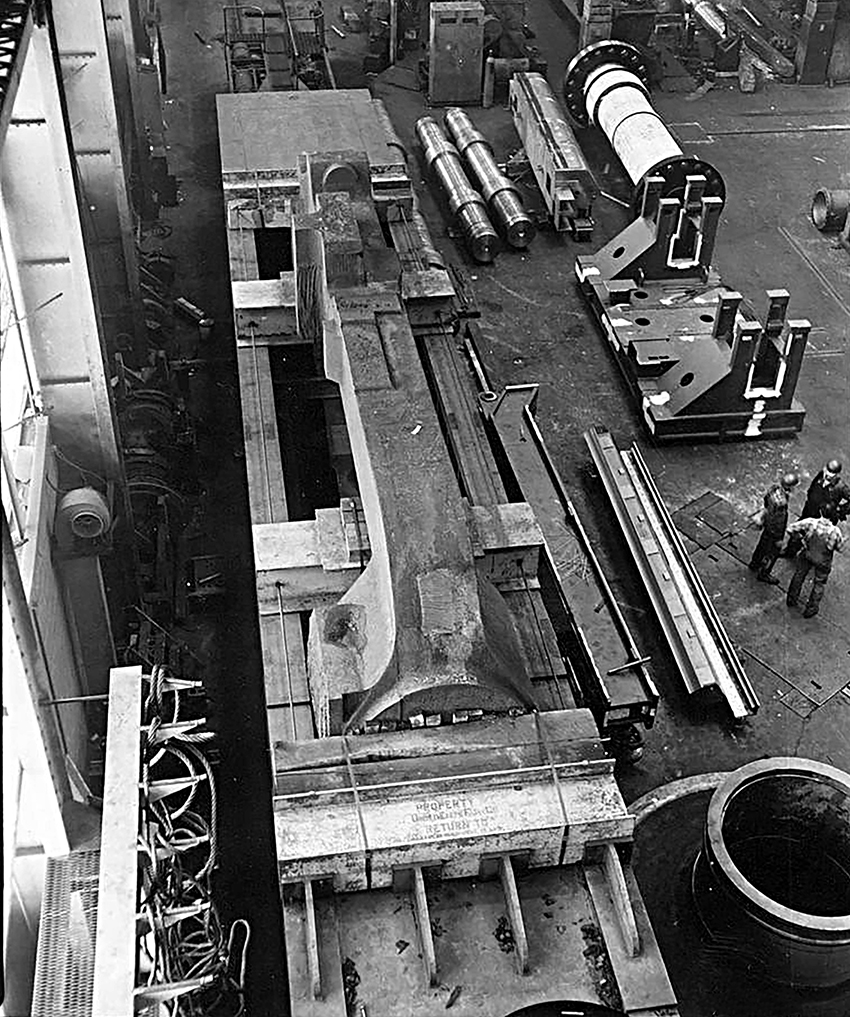

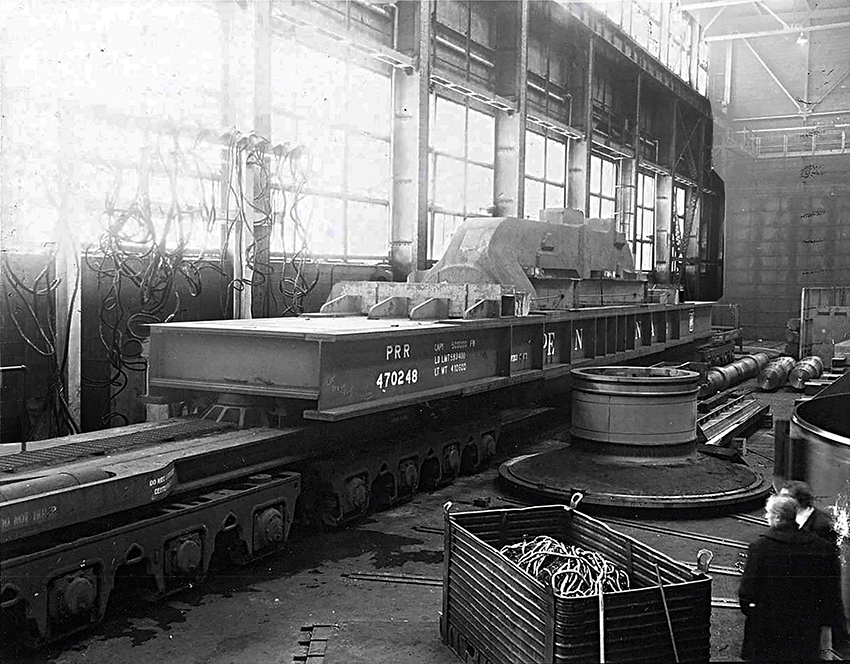

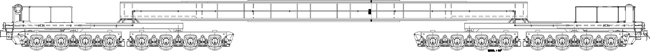

10/10/23 - The research and production of this project was completed quite some time ago, but I was just presented with some new information that I found very interesting for multiple reasons. The series of photos that follow were offered by Mr. Hans Schmitz who at the time the photos were taken, worked at Dominion Engineering in Montreal,Quebec, Canada. The photos were saved from the trash which seems to be a common situation with many items of interest when it comes to railroad historical research. The photos were of particular interest to me showing the loading technique used for the load, the fact that the FW-1 made at least two trips to Montreal and traveled on the Canadian Pacific mainline during it's travels. The load shown was not exactly the same as the one the FW-1 was originally designed to carry, but this 210 ton cast frame used for a very large steel rolling mill was very similar. These frames were used in pairs requiring at least two trips.

The overhead photo and one below show that the loading was very similar to that provided with our FW-1 model

Final preparations are being made for the long trip home in the photo above and the FW-1 begins to move out to the spur heading for the Canadian Pacific mainline.

6/28/21 - The available model versions have been updated above. 12/06/19 - A new information heading has been added to this page to make it easier to identify what model versions are still available for purchase, see the listing immediately above this post. 3/30/17 - The Downloadable order form has been updated to indicate the available versions of this project. Please check with us directly before ordering to ensure that your desired version is still available as two are very limited. 2/21/16 - I have received several inquiries of late regarding the availability of this project, I am happy to advise that there are still several models available for immediate delivery. The basic versions of the two model types are available, for more specific information please contact me directly for further information. 11/04/15 - I Unfortunately have to issue a warning that the same people involve in selling the junk N5 cabin cars are also involved in peddling junk flat cars as well. Beware if you are offered an FD-2 or FW-1 at discount prices, odds are that they will be the same 'fine' quality as the cabin cars that the sellers have been lying about and misrepresenting. If a model you are considering for purchase does not have a Kohs & Company serial number plate and a matching signed certificate, it's not a Kohs & Company model. You can read more about the activities of the deceptive sellers on the N5 cabin car project update page. 8/11/15 - The shipping continues!! Slow, but sure, I'm gaining speed and the reports on arrival condition have all been good. I failed to mention previously that the added detail that you see in the photos related to positioning of the loads was an added extra once the models arrived here in the states, so all that work is being done here in addition to the inspection and packing. It was difficult to come up with tie-down detail, particularly for the generator load, that would be practical in terms of shipping and that if left in component form, could be easily assembled by the average owner. I feel that I reached a conclusion that is affective in terms of prototypical appearance and yet is easily put together without special tools or skill. There have been numerous requests for additional version and detail photos and they will be coming soon. The effort at this point has all been concentrated on delivering models to new owners and not so much on promoting what has been accomplished with this project, owners should have the opportunity to experience the models first-hand as soon as possible. 7/19/15 - Just a brief update regarding the shipping of this project; it is proceeding and picking up speed. Due to the size and configuration of this model is presents some unique concerns when it comes to shipping. I did some initial nearby shipments to evaluate the packaging design and since those shipments have modified how the models are packed in their boxes. The subsequent shipments have been more secure and the concerns have been alleviated. In addition to the shipping it's a particularly busy time as our N5 cabin car project near completion and work continues on the Big Boy project and that all requires daily input. Inquiries about current as well as future projects are at an all-time high, it's always a balance between everything that needs to be done! 6/12/15 - Good news the flat cars have finally cleared US Customs, I received notice at 4:00PM ESDT and just finished moving the shipment from Detroit Metro Airport to my workshop at 10:00PM. Apparently customs officials understood how fond the owners would be of their new models and had to make sure that the paint was suitable for licking and kissing. Extra inspection days were required this go around to make certain the paint is safe for human consumption! All looks well so far and I'll be getting organized over the weekend so shipping can start first thing Monday. Again, thanks to all for your patience, I'm pretty certain that you are going to be pleased. 6/07/15 - Just a brief update to let interested modelers know that the flat cars have arrived in Detroit as of today. The hope is that they will clear customs tomorrow and will be available for pickup tomorrow afternoon or Tuesday morning. The shipping to customers will start immediately! 6/03/15 - Good news, after great frustration, even more than usual, the flat cars are scheduled to be delivered to Detroit in the next couple of days! They are coming by air freight as usual, but it seems that the space is even more tightly allocated than when I arranged my last shipment, needless to say, the cost was impressive! The models will start shipping out to their new owners just as soon as the models are in my hands. Anyone with an outstanding payment may want to consider getting in line for delivery. I will let owners know as soon as the models start moving and I will do my best to provide the tracking information for the individual deliveries. Keep in mind any vacation days that you may have planned so we can avoid having a mode sitting on your doorstep unattended for an extended period. Despite requests, UPS has been known to leave packages. 5/16/15 - A parting shot......the boxed flat cars just prior to being covered up and sent out the door headed for a flight to DTW, Detroit Metropolitan Airport. This is a beautiful site for me, a project fraught with many perils brought to a great conclusion. Updates on deliveries will be coming soon.

5/13/15 - Just a couple of brief items to mention this day. I have had a couple of inquiries from reservation holders for this project that failed to order the accompanying load for the car ordered and they were wondering if loads were still available. I do have just a couple of loads available, so if you are interested in a load for your model, please let me know and I'll do my best to see that you have the opportunity to purchase one. It was mentioned to me today that the reject/junk FD-2 flat car production sample model created by my former builder-gone-bad was offered for sale at a price of $500 complete with junk load. In short, I was asked what the problems were with this model, the following are the main issues over and above the substandard construction and incorrect paint colors: incomplete and incorrect deck detail on the carbody, incomplete and incorrect seam detailing on the underside of the carbody, incomplete and incorrect detail on the extended bolster decks, non-scale wheels, incorrect journal boxes, incorrect truck sideframe castings, incomplete and incorrect truck suspension detail, incorrect brake piping detail on the trucks, missing brake piping and detail on the carbody, missing mechanical brake detail on the carbody, missing data plates and the entire model was not properly ballasted for operation. Essentially, none of the corrections were made to this 'production sample' following the critique of the original sample models, the reason the project was scrapped with the original builder. The same issues apply to the FW-1 sample that was being offered for sale at a recent show, except that the carbody on that model had it's own unique problems. The purpose in mentioning this is to hopefully protect potential buyers from the misrepresentation that has been associated with the reject/junk models that have been offered for sale in the marketplace. 5/10/15 - I wanted to share a couple of additional photos taken during the inspection of the production that I did not post while overseas. The photo immediately below shows the new scale profile wheel-sets. There is also additional detailing not included in the previous sample models photos, but that will be covered when the new set of photos is completed in the studio setting.

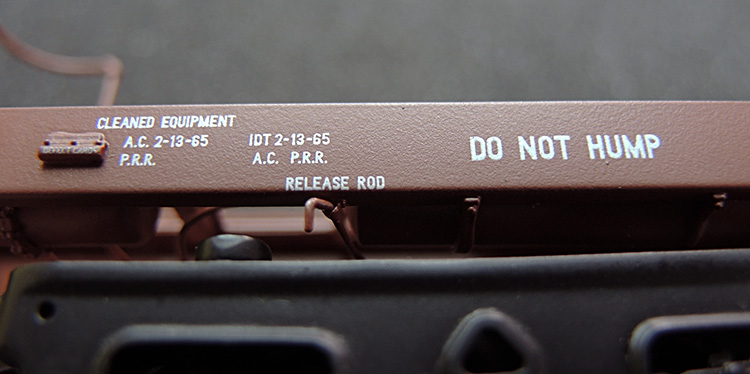

The photo below provides an example of the quality of the graphics applied in this project and some of the finer details as well. See if you can find the words "Defect Cards" somewhere in the image. Not only has the manual brake release levers been added to the models, the very small bracket detail that supports the rods has also been added, a further example of the extremely clean and precise soldered employed throughout the project. Details regarding the delivery of models to reservation holders and new orders will be forthcoming in the next couple of days. We are in the hands of freight forwarders and airlines at this point, but I will be pushing for fast service.

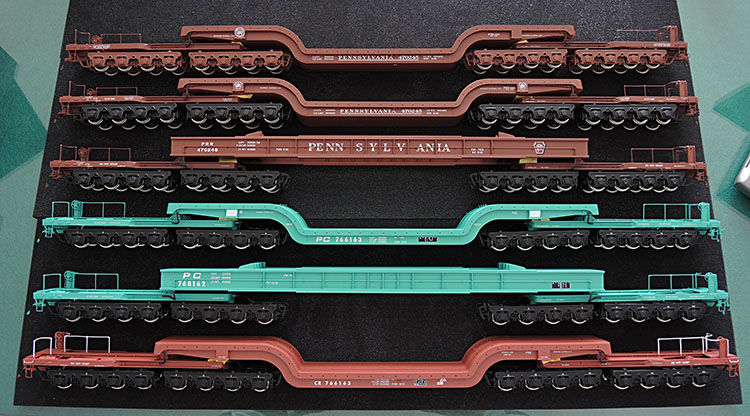

5/05/15 - The final inspection of the FD-2/FW-1 flat cars is complete! It has seemingly taken forever to complete this project, but the end results are better than hoped for at the outset. The level of detail and fidelity to the original design is without compromise. Some of the special attributes noted during the inspection process were the most consistent paint work in terms of difficult to reach areas and overall finish as well as the most 'crisp' detailing, particularly the piping and underbody detail. I never noticed some much as a drop of misplaced solder. Due to time and logistics, it was difficult to get many detail photos, but be assured that a new full set of studio photos will be processed as soon as the models arrive in my shop, which will be just as soon as the airfreight arrangements are completed. Shown below is a full set of all six versions of this project, starting with the three Pennsylvania Railroad versions at the top, the two stunning Penn Central versions in the middle and the Conrail version at the bottom.

My new favorite version from this project is #6, the Penn Central FW-1. Vibrant color is something not typically experienced with our projects to date, but the Penn Central green certainly takes care of that! The color is even more striking in natural lighting, I had the limitation of working with fluorescent lights for the photos. I feel certain that all reservation holders will be well pleased, regardless of what version they chose.

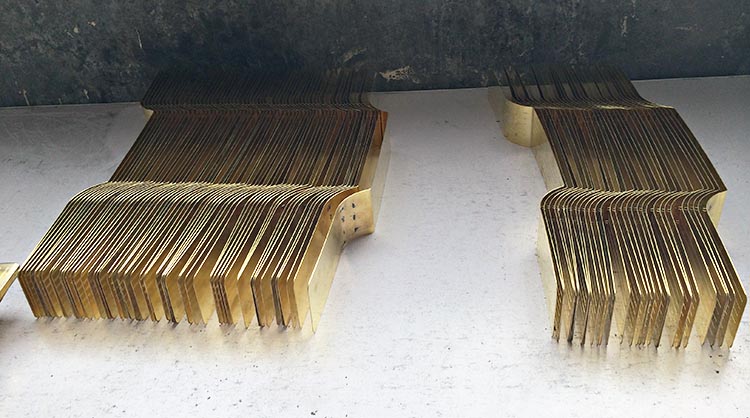

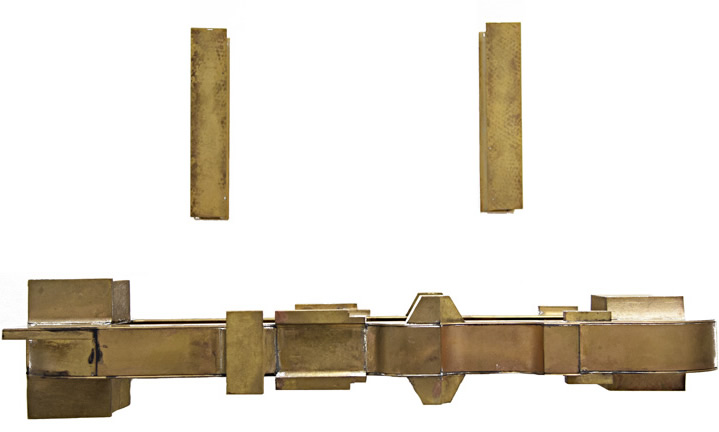

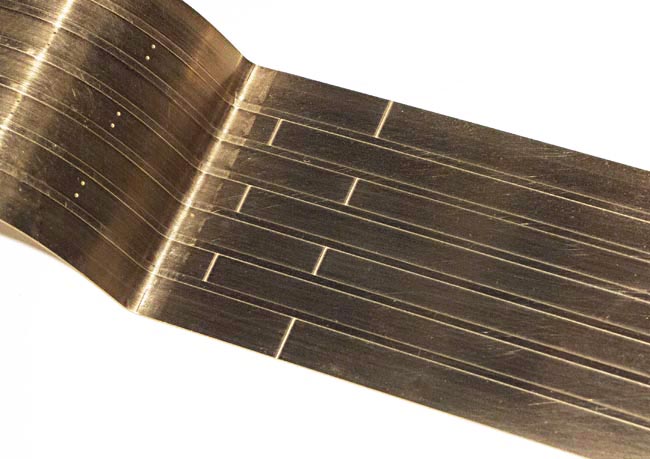

One last note; be advised that one of the less scrupulous 'characters' in our hobby is currently trying to sell the two junk original production samples from this project that were created by the builder that I dumped for unethical business practices. Despite what he will tell you (anything basically), there is nothing correct about the models including the colors. He has also been active in trying to peddle the junk PRR cabin cars using lies and deception, please be forewarned. 4/11/15 - The final notices for all reservation holders have been in the mail for several days now, so if anyone does not have theirs in the next couple of days, please let me know and another copy will be either E-mailed or sent by USPS again. All international customers should have also received an electronic copy of the final notices by E-mail. Photos of the production models and the inspection process will be coming shortly. I know that many enthusiasts are anxious to see some of the alternative versions of this project and I will make certain to show all of the versions as soon as possible. 3/25/15 - It has been a very long time coming, but we are finally at the end of this project and the final inspection date has been set! Those that have had the opportunity to see the production sample models at the last couple of shows that I have attended have been particularly anxious for this announcement so they could look forward to taking delivery of their models. I am certainly not happy about all of the delays, but the end results are even better than originally planned so that is of some consolation. The final notices for the flat cars and the loads are being prepared and will be mailed by tomorrow so that we'll be ready to start shipping by the time the models arrive here in my shop. I will continue to update regarding the shipping and delivery dates and there will be the usual photos posted taken during the inspection process. Thank you again to all that have been so patient in allowing this project to come to fruition! 1/26/15 - The production of the FD-2/FW-1 flat cars and loads is well along in the schedule towards completion as of this date. The series of photos below documents the construction that has taken place and the models are currently being painted. There will be a few more construction photos added, but I wanted to pass along what is on hand at this point before any more time passes since it will be time to mail the final notices for the project in the very near future. The photos will not show every step that is involved in the construction, but they will provide an overview of the process. Once the castings are produced and the sheet brass components are formed, it's all hand work from that point on. The photo below shows a quantity of upper deck sheets for the FD-2 'flats' that have already been cut to shape, etched to create the correct seam ribs, formed for the correct contours and punched with locating holes for brass castings that will be soldered in place as the production continues.

In this photo you can see the results of the photo-etching that has taken place leaving the raised ribs for the seam caps. The tie-down loops have already been soldered in place and some of the side deck detail has also been soldered in place.

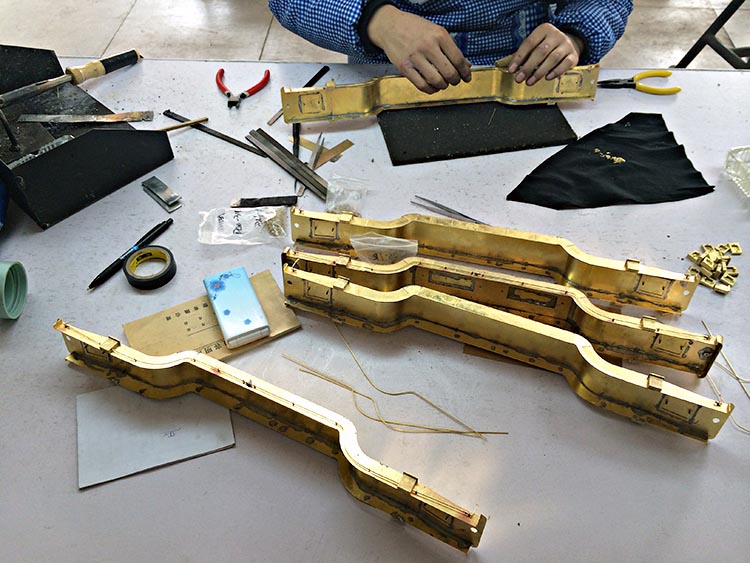

While the upper decks were being prepared, many of the same processes were used to create the bottom side sheeting. Again, the components had to be cut to shape, etch for seam detail and formed to the correct shape to match the contours of the upper decks. At this point the side plates and related detail have to be soldered into place and in the photo below that process is under way.

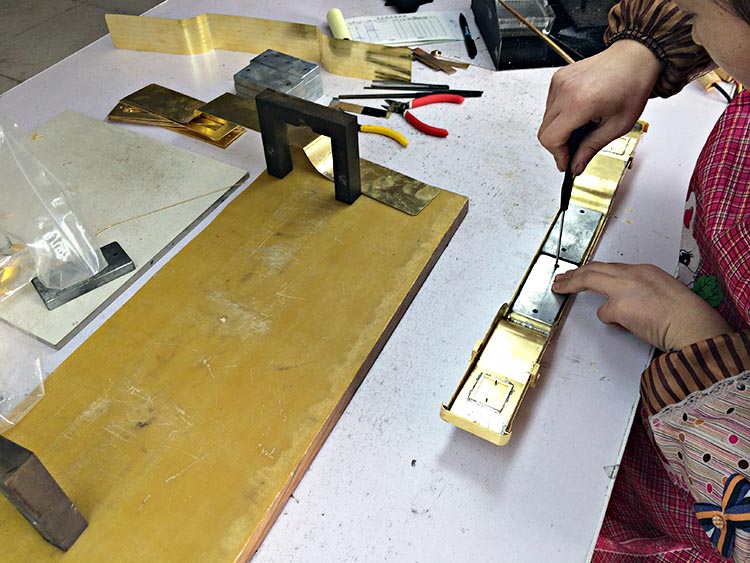

In this photo you have a better view of the side plates be soldered to the bottom sheets. The end bulkheads also have to be positioned and soldered. You can see the technician using positioning 'jigs' to help align the parts to be joined so that there is great consistency from the first model to the last.

Below is another view of the side plates being soldered into place.

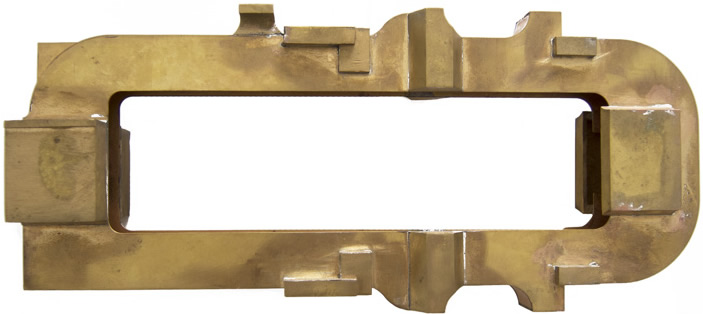

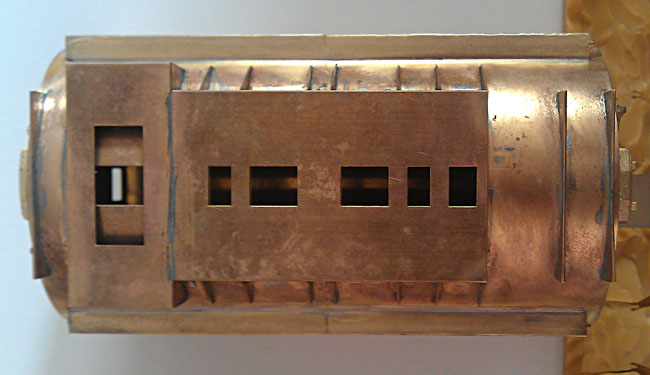

Once all of the side plates are installed, the next process is finishing off the access panel openings, you can see those rectangular openings at either end of the bottom sheet. There is an inner frame that must be soldered to the inside of the bottom sheet and to that is attached the cover plate that is held in place by small machine screws. A common problem that many modelers have experienced with brass models is that with time, you will often see what looks like white mold or corrosion leaching out of seams or soldered joints and sometimes under painted surfaces. This is caused by insufficient cleaning of solder flux prior to painting or residual acid used for cleaning the brass being trapped inside assembled components where with time it leaches out and causes the white 'crud' that many poorly built models suffer from. With our big flats, access panels were built into the construction in areas not seen when the models are assembled so that the inside of the models can be thoroughly cleaned and dried prior to painting. This was an extensive effort to ensure the long-term quality of the models.

With the access panels now in place, the addition of the remaining detail takes place on the bottom half of the carbody. This included external gusset detail on the side sheets, piping and air fittings and other structural features that are separately applied for authenticity.

Here you can see pipe fittings being added and carefully aligned.

With all of the external detail in place, this group of components awaits the next step in the sequence.

The alignment of the work done to this point is again checked using a custom built jig designed expressly for this purpose. Once the alignment is verified it's on to the last step for this portion of the model.

With the alignment of the bottom plate set, the internal ballast can be added, this will make certain that the completed models will track correctly on minimum radius curves.

With the internal weights installed, the upper and lower halves of the model are assembled to form the completed carbody.

Another inspection takes place at this stage to make certain that the completed carbody is approved for painting preparation. If any adjustments are required they are accomplished before leaving the assembly area.

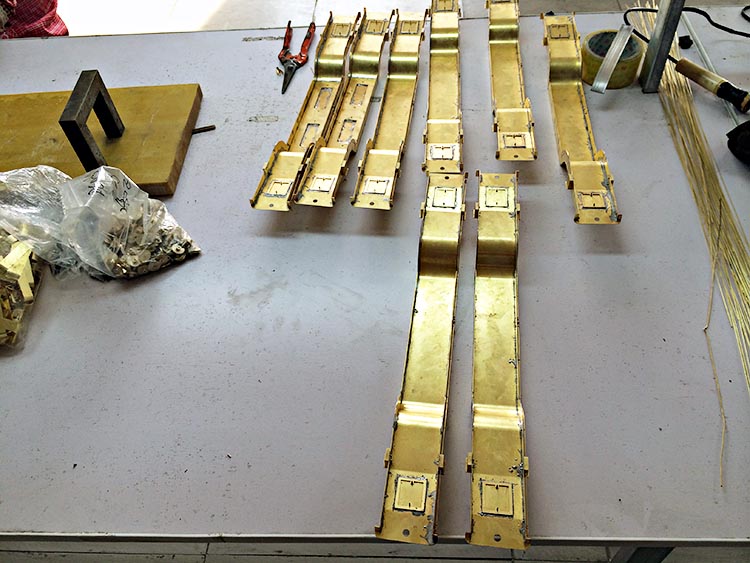

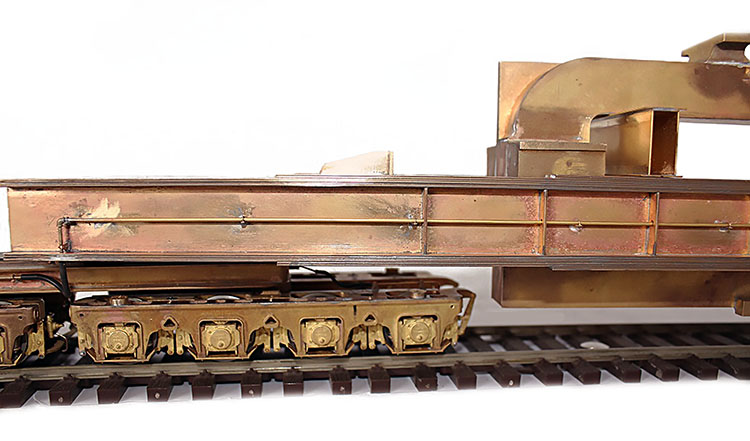

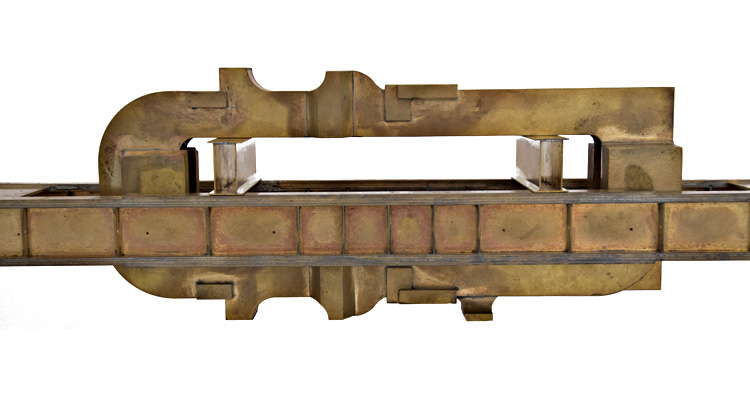

To this point I have only mentioned the FD-2 version models, but below you can see the FW-1 carbodies taking shape going through many of the same steps as described above. Obviously the design is different so the processes are not exactly the same, but the progressive nature of the assembly and intermittent inspections assures consistent quality of the FW-1's as well.

Another view of the final inspection station where any fine finishing takes place.

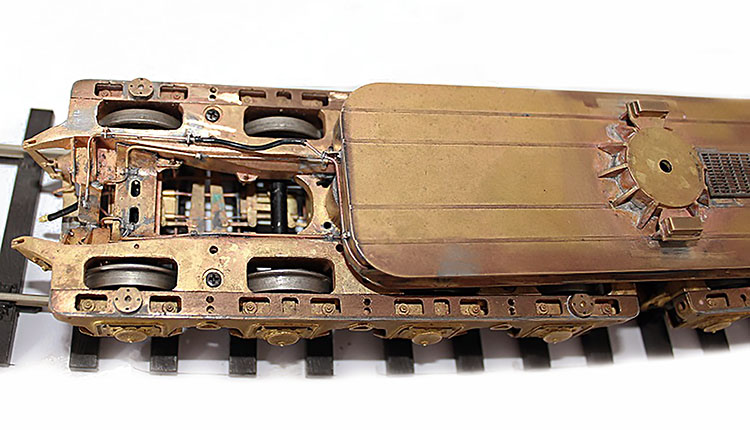

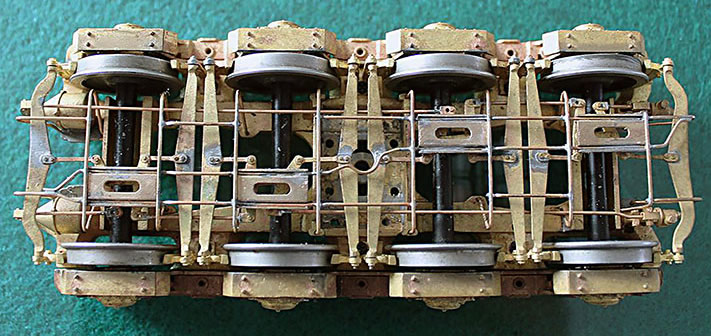

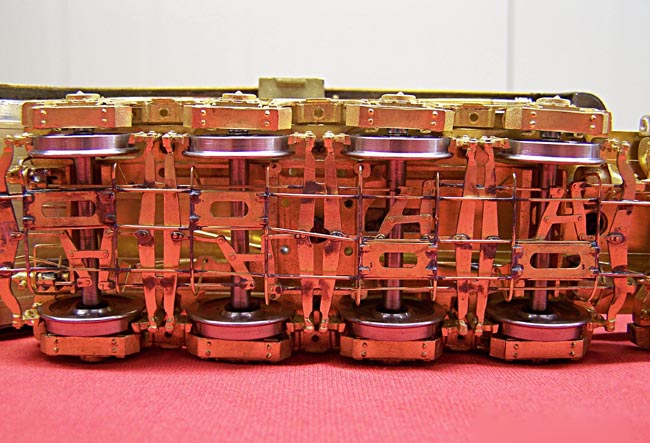

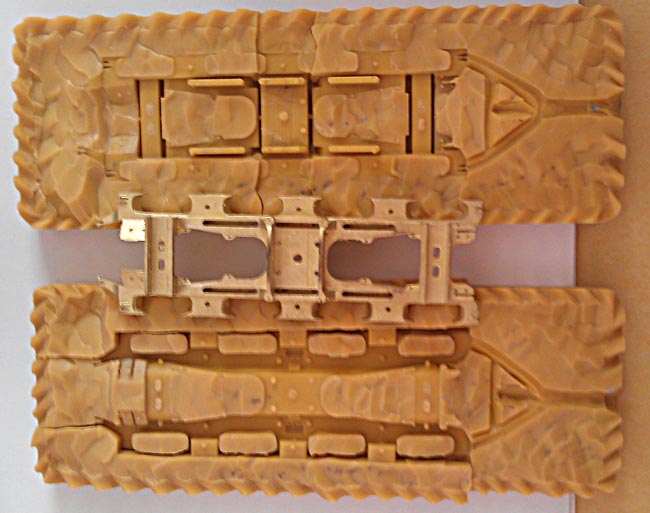

In another area of the facility, the span bolsters and trucks are assembled from the hundreds of pieces required for each complete unit. Again you can see the custom made jigs used for aligning parts during the final assembly. The ability to assemble so many parts using a soldering iron is a true art, adding pieces without affecting the work already done is almost a 'black' art, if you have every tried it, you understand.

Here you can see two completed span bolsters minus the trucks.

While the flat cars were being assembled, the loads also had to be built in much the same way as the cars. Extensive soldering was required for each load which is a sophisticated model in it's own right.

Here you can see the FD-2 generator turbines ready to go to the paint shop where they will be thoroughly media-blasted, acid washed, rinsed and dried in preparation for painting.

12/10/14 - The response to the new flat car photos has been a bit overwhelming, but thank you to all that have sent messages or called to express their excitement regarding this project. The new builder is taking all matters to a new level, it would have been very easy to deliver the caliber of model that is seen in the latest photos, but as the production is progressing, additional improvements and added details are being incorporated into the final build that will conclude late next month. Journal boxes with improved detailing, improved piping detail and added data plates are just a portion of what is being done beyond what the photos represent. Needless to say, I am very exciting about the results of the project, the fact that it is drawing to a close and most importantly the fact that my reservation holders will be well rewarded for their great patience when they see their new models! 12/02/14 - The flat car production samples are being photographed now and a full set of new images will be posted later today. The image below is of the version #1 FD-2 complete with it's load. You will see in the new photos that the load is a highly detailed brass model unto itself, there was no compromise made to simply fill the load space. The incredible patience of my reservation holders is about to pay off, the production will be completed next month. I can also confirm that the minimum operating radius for both car types is 48" on proper trackwork.

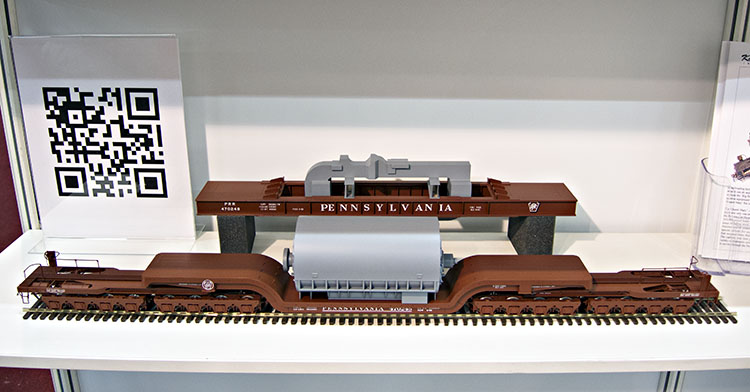

11/22/14 - Shown below are the painted production sample flat cars that I have on display at the Modellbahn Show in Cologne, Germany. The completion of production is set for the end of January 2015, so this project is finally just about wrapped up. The customers that have had the opportunity to visit me at the show gave the models rave reviews for the quality of finish and the detail work of the new construction. As soon as I return home the new samples will be photographed in studio so that you can see more closely just what the models look like up close. It is very exciting to see the models done the way they should have been many months ago!

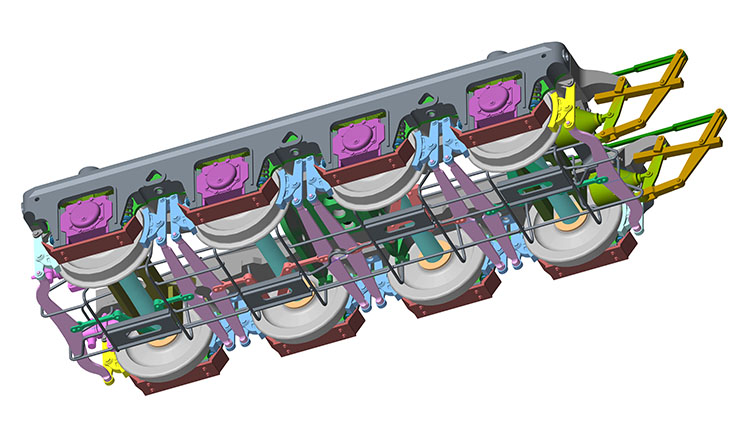

11/13/14 - You have already seen the latest truck samples in previous updates listed below, but shown immediately below is an image capture of the design file used to create the parts for the samples and which is driving the production. I've shared image captures from the design files of other projects we are working on and I felt the truck image would also be of interest. It is difficult to describe just how valuable this new approach we have taken with our development really is. The ability to 'see' the components or complete model before it's physically built can go a long way towards continuing to make brass model projects financially viable by eliminating waste and time in the process.

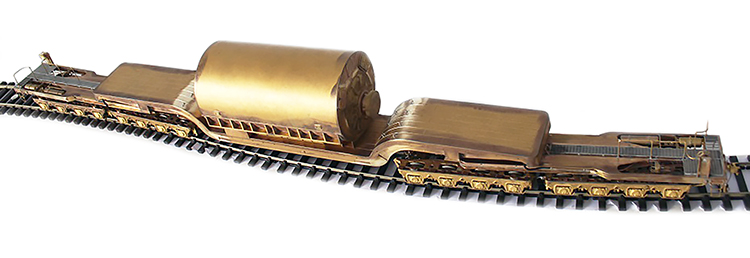

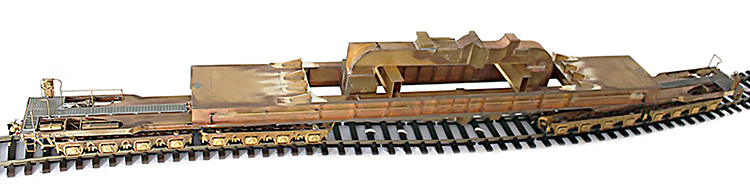

10/15/14 - Shown below are several photos of both the FD-2 and FW-1 flat car samples prior to being painted. Corrections made and the loads ready to go, the project is well along towards completion at this point. In these overall photos, you begin to get an idea of the massive size of this model, truly an impressive sight!

In the photo immediately below, you can gain some perspective on just what small radius curves the model can negotiate. The curve track to the right in the photo is an approximately 48" radius, this unit will easily handle curves that a typical scale length passenger coach would require.

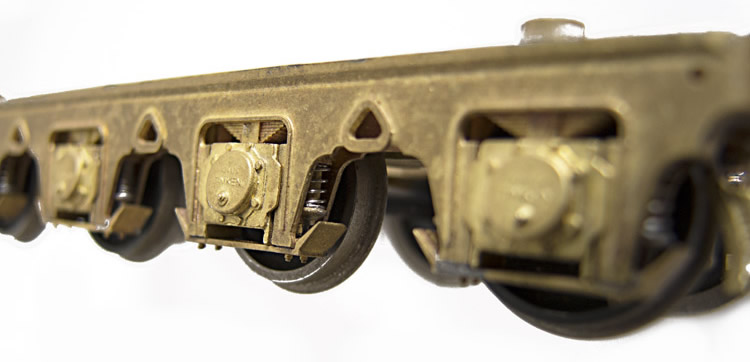

With the two unique truck assemblies installed the parts count for this unit is approaching 1,000 component parts, then it's times two when you include both truck units. There have been no corners cut on this project, every part in the original prototype design drawings has been incorporated in this model.

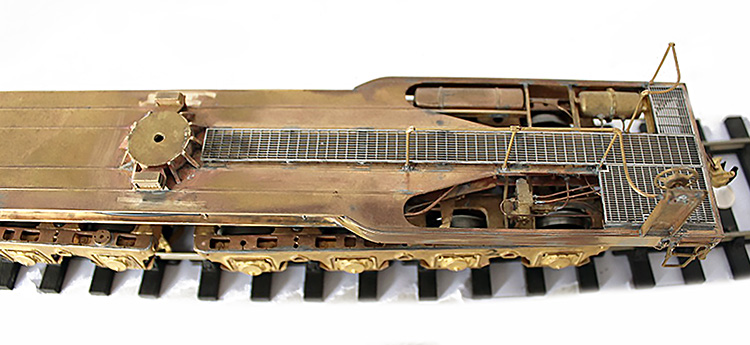

From the stainless steel walkways to the complete brake piping, all the details are there, even parts that you do not see when the model is fully assembled.

At the other end of the truck unit you can see some of the piping detail that is not visible except when the trucks are fully articulated. The parts belong, so they are included.

Below is an overall perspective of the FW-1 including the precisely scaled load. There will be wood shoring located between the load and the end stops when the model is complete to keep the load correctly positioned, the same arrangement as the prototype.

Again in the photo below you can see how well the model articulates through tight curves. The FW carbody is only slightly shorter than the FD drop-center carbody, so the overall length is nearly the same.

This view provides a closer look at some of the prototypical detailing of the carbody and the piping detail unique to the FW version model. The piping arrangement is part of the reason that the carbodies are not directly interchangeable with the truck units. The lowest portion of the load rides at about the same level as the bottom side of the drop-center carbody.

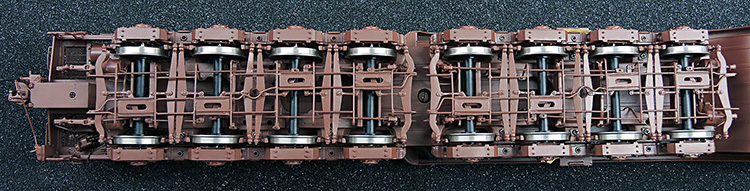

9/26/14 - In the previous update on this project, you saw the partially completed redesigned trucks for our flat cars, shown below is a completed sample. Each truck is assembled from more than 300 individual parts! By far the most complex truck that we have ever modeled and I suspect ever will model, it demonstrates just how committed the new builder is to excellence and being the best.

This sample is shown with our old 145 standard wheelsets, the production model swill have our newer scale dimensioned wheels developed from our UP Challenger project.

As previously mentioned, the suspension is fully equalized and utilizes functional coil springs per the prototype design. All of the journal boxes are equipped with sealed ball-bearings for smooth maintenance-free operation and all of the appropriate cast lettering is present on the truck components.

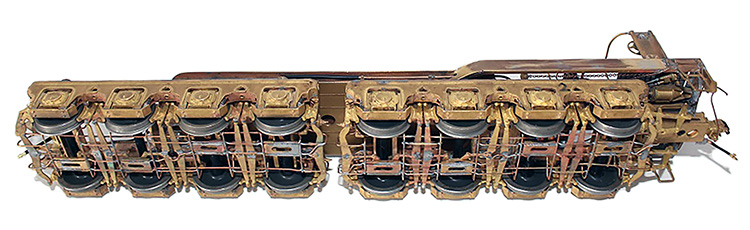

This view of the underside shows just how complex the construction is. All of the safety rigging for the brake system is present as is all of the actual brake detail. The frame construction follows that of the prototype as well, a true miniature scale model of the real thing!

9/8/14 - It has taken longer than I would have liked, but under the circumstances created by the original builder handling this project, I am very excited about where we are with this project now and with our rolling stock effort in general. The new building arrangement not only has allowed for a complete redo of this project with every necessary correction made and numerous improvements also incorporated, it has laid the groundwork for exciting new projects that otherwise may have never been realized due to the rapidly changing brass modeling industry in Korea. We now expect to complete this project by the end of the year. The photos below are a sampling of the latest work that has been completed for the FD-2/FW-1 project. The photo immediately below shows the completely redesigned carbody for the FD-2 flat car. The deck seam detail, tie-downs and gusset detail on the structural frame members have all been redone to correctly replicate the original prototype. Just as important are the changes made to make sure that the quality of the model is not compromised by the passage of time. During the production process and in preparation for painting, caustic solutions are used to clean and etch the metal surfaces to insure that the paint adheres correctly. If any of the solution is trapped or allowed to dry and ultimately painted over, it will eventually leach out of soldered seams and degrade the paint and often times leave a white residue that unfortunately is commonly seen on many models that have aged less than gracefully To avoid this situation, access has to be provided to reach and clean the inner surfaces of the carbody, the original design and construction did not allow for this part of the preparation process.

The trucks have been completely redesigned as well. The suspension is now fully equalized and incorporates functioning coil springs in all prototypical locations. The side frames now also have the correct see-through casting openings not present on the original sample models. Every journal box incorporates a sealed ball-bearing unit for the stainless wheel sets to run on.

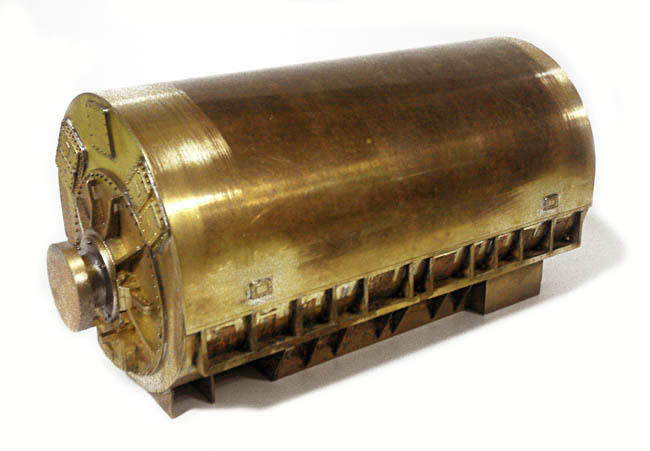

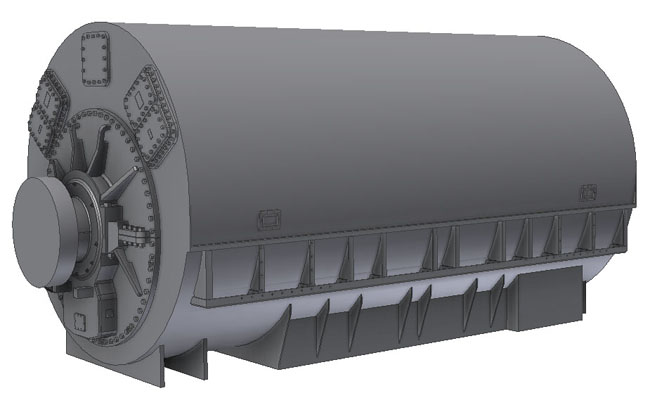

The generator load for the FD-2 is built from all brass fabricated and cast components, it is an exact scale model of the Westinghouse generator turbine units commonly transported on the FD-2. No expense has been spared in modeling the detail required on every part of the load, notice the specialized large castings used on both ends of the unit.

The photo below shows the generator load in place on the carbody of the FD-2. The flat car on it's own is an imposing sight, but with the load in place, it becomes a truly unique miniature replica of one of the most famous pieces of rolling stock equipment to ever run the rails of North America.

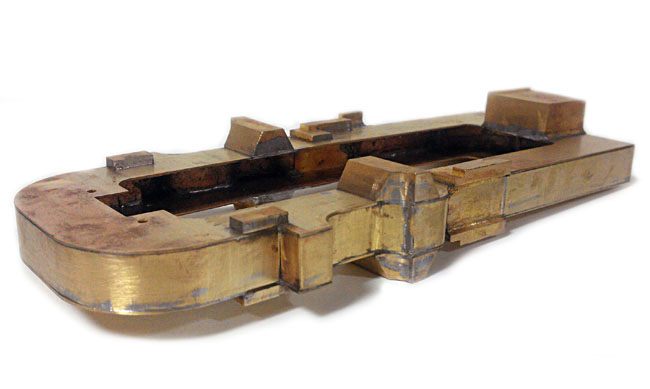

Just as the FD-2 has been completely redesigned, the FW-1 has also had significant changes made to correct errors evident with the original builder's samples. Starting with the carbody, all of the support ribs have been correctly realigned and added to and the layering of the horizontal sheets of the side frames have been enhanced so the appearance matches the prototype. When you look at the upper and lower edges of the side frames you actually see the layered metal that makes up the main structure of the carbody.

The closeup below shows the layering of metal (circled in red) mentioned above.

The quality of the new FW-1 load sample is substantially better than the original builder's sample. Again fabricated from brass components, the fit and finish is better and the overall construction is more faithful to the design provided for the stamping machine frame. The only element missing is the inner skin which will close off the frame section, this is yet to be added.

The photos above and below show the stamping machine frame load in place on the FW-1 carbody. The FW-1 was originally designed to handle this specific load by the company that built the stamping machines. While the carbody was owned by the machine company, they had to lease the use of the truck units when they had a scheduled move. The Pennsylvania Railroad eventually purchased the carbody from the machine company and the unit was used for multiple other moves that required maximum height clearance, taking advantage of the open well design of the carbody.

8/19/14 - It seems that our last mail update that went out to our PRR N5 cabin car reservation holders went well and I have not heard from anyone that did not receive the mailing. As a result, I am proceeding with another attempt at an update mailing for this project. It is being processes now and should be in the mail tomorrow. 7/14/14 - With an updated update for the PRR N5 project in process, a new updated update for this project will follow close behind. I am hoping for better luck with this mailing! With the first of the new N5's expected later this month, the newly updated samples for the flat car project are nearly complete and will follow in production immediately following the cabin cars. More details are included in the new update. 6/24/14 - I have heard from several customers that they have not received their project updates in the mail, as a result, I am mailing new copies to everyone to make certain that all reservation holders have the latest information. There is no way to explain the postal service situation! 5/20/14 - With a last minute visit to Korea arranged following the last update, I decided to hold that postal mail update until the most recent visit to Korea was completed, so I would have the latest first-hand information. The promised postal update will now be sent out in the next few days. 4/28/14 - The updates on this project have lagged behind other projects, but that has not been intentional. After the completion of our UP Challenger project, the focus of our production efforts shifted to the PRR N5 cabin car project in an effort to push that project along as quickly as possible. As I have explained previously, our new builder for rolling stock is also doing this project and it is following behind the cabin cars in the production order. A written postal mail update is in the works for reservation holders and will be going out shortly to explain where we are in the process. 8/04/13 - With a second trip to Korea in the last two weeks to work specifically on our rolling stock, I can confirm that the development work for the FD-2/FW-1 is near complete and ready to implement as the work on the N5 cabin cars moves ahead. Once I figure out where I am after this second trip (for those of you who travel and have to deal with jet lag, you know what I am referring to) I'll be posting more detailed update information. 6/03/13 - More update details are coming following my recent return from Korea. As I get caught up with correspondence from many of you I will be highlighting what has been developing with our new builder on this project. Check back very soon! 2/23/13 - Following my most recent visit to Korea to inspect and follow up on projects, I am happy to report that our FD-2/FW-1 flat car project is in very good hands. Discussions and preparation as well as initial work on the project have been going on since the end of last year and what I had been told was seen first-hand during this visit. The situation with the original builder of the N5 cabin car project, as well as this project, that had brought everything to a stand still has obviously been very difficult for all concerned. The new builder has picked up with the corrected designs from which the original builder had completed flat car production samples, although I never saw them, and laid out a plan to not only meet the original goals, but also implement serious improvements. The nature of the improvements include features such as scale wheels with adjustable gauging as well as design improvements that will insure the archival quality of the models for many years. The financial challenger created certainly made things 'interesting' as well. With the cooperation of the new builder, we have had to look for ways to cut costs without compromising the projects and any thought of Kohs & Company making a profit was dismissed. The positive side of this effort is that it will make future projects more doable than they otherwise would have been. I have routinely discussed the escalating costs of materials and labor that have been a huge threat to particularly our future rolling stock projects, the new approaches being implemented will help to alleviate some of that pressure. I can't go into too much detail since I do not want to make those challenges any easier for other builders. As the N5 and flat car productions move forward, we are actually producing component parts for six different projects at the same time. When there is a component that can be used on multiple projects, those parts are being stockpiled to save not only money, but time as well for our new projects. This approach requires extra effort and planning, but all involved feel that it will pay dividends in the future. One last important comment on the overall situation. Despite how unethical the actions of the original builder were, it is highly unusual for another Korean builder to take sides with an American importer which is exactly what has happened. For that reason, until the N5 project is put to bed so to speak, I will not be divulging too much specific information regarding the new builder. He will have his praises sung load and clear when the time is right and many of you will have the opportunity to meet him this summer at shows here in the states. I again thank all of the reservation holders for this project, your patience has been and is sincerely appreciated, it will be rewarded with a fantastic finished product this summer. More news will be coming very soon! 12/11/12 - Unfortunately, the scheduling of non production efforts are by necessity done with my best intentions, but often take a back seat to the needs of the day in Korea. As a result, the written project updates and account statements have just been mailed. There are separate statements for the car reservations and the load reservations so there will be no confusion. Site updates will follow shortly. 11/23/12 - A project update for all reservation holders will be going out early this coming week, updated account statements will be included. I am happy to advise that we are again making good progress on this project following our major setback during the summer. Further updates will be posted following the update mailing to reservation holders. 11/09/12 - A new written update for reservation holders will be going out early this coming week. I just completed a week of work in Korea and have lots of information to share. More very soon. 7/15/12 - A written update has gone out to all reservation holders for this project, updates will continue to be posted here once those recipients have a chance to review the written updates. 5/25/12 - An update on the project is long overdue and that will be happening here as well as in written form to all reservation holders. Based on the unusual number of comments from customers about not receiving reservation confirmations for both flat cars and loads, I am going to rerun the confirmations and send them out again to make certain that everyone receives their notice. It seems as though someone took a handful of mail from the system and trashed it rather than delivering it this time around. Postal delivery seems to become a bigger problem with each subsequent mailing and unfortunately there is little that I can do about it except resend what turns up missing. 12/20/11 - The first group of PRR N5 production models are due to arrive any time now and included in that shipment should be the painted production samples of the FD-2, FW-1 and thier respective loads. I already have photos of the completed models that were provided by Mr. Sin the builder, but they were not of adequate quality to post on this site. New photos will be processed as soon as the samples are available. Stay tuned! 11/12/11 - The FD-2/FW-1 flat car project is moving along nicely at this point. As many of you are aware, I have just recently processed the reservation payments for the flat car loads and I will be sending out order confirmations as quickly as possible, as I wade through my pile of paperwork. Many thanks for your patience as you have waited for me to take your money, I greatly appreciate it, both the patience and the money! Shown below is the newly completed production sample of the FD-2 version of the flat car. Until now I have not inumerated all the changes that have been made, but the deck is a completely new design that was mentioned in a previous update, the trucks have been completely redesigned and extensive new detailing has been added. I am anxiously awaiting the arrival of the painted sample model along with the completed and painted load samples which is iminate. The three photos shown were taken in Korea.

This next photo shows the underside of the completely redesigned trucks. The side frames and all of the spring detailing has been greatly enhanced since the first sample was completed and the complete safety rigging for the brake system is not present. This sample shows our previous Kohs & Company profile wheelsets, the delivered production models with have the scale wheelsets that we previously described.

The final photo shows the most recent status of the flat car loads, again the photo was taken in Korea. The Westinghouse load in the background is basically complete and ready for paint. The FW-1 load in the foreground is yet to have the interior skin placed to close the body of the assembly. This photo should provide a better appreciation for the number of parts that must be assembled to give this load the proper shape and characteristics. The two tube like structures standing vertically in the middle of the load are the two loading girders that will be included with the load model so it can be properly loaded on our FW-1. You would not believe the amount of research that went into developing this FW-1 load, but it will be worth it when placed on the 'flat'.

8/09/11 - The photo below shows the revised deckplae detail for the FD-2. To replicate the seam detail correctly, it requires the use of multi-level photo-etching techniques that are not often used by other builders due to the difficulty and expense. The process is greatly complicated by having to form the contours and shape of the deckplate after the photo-etching process has been completed. Special skills are required to accomplish this without flattening the etched detail or making it less than uniform in appearance.

Shown below is the nearly completed Westinghouse generator load for the FD-2. The castings have been completed and installed and only some minor detailing and adjustments are required at this point. You can see the number of parts required and as mentioned before, this has turned into a model project in it's own right.

The nearly complete load sample for the FW-1 is shown below. You can begin to see the very complex shape of the stamping machine frame with it's many bosses and protrusions. There are a couple of detail parts yet to be added and the inner surface also has to be completed. When complete, it will provide for a unique and interesting addition for the FW-1.

6/29/11 - Shown below are more new photos showing the progress on our flat car and load projects. The first photo shows the master pattern for the redesigned truck bolster and the mold used to replicate the part in cast form. The mold is a specialized silicone material that was selected because of the size of the part to be replicated.

The next photo shows the master pattern and mold for the generator load end cap. The master pattern is an assembly of machined and fabricated pieces that must encompass all of the detail required to be on the final cast part. Special skill is required in designing a part to be cast to make certain that not only a mold can be made, but that the part can be removed from the mold, otherwise the mold is of no value. If all design factors are not taken into consideration, certain types of detail can permanently capture a part in the mold and make it impossible to remove the part without destroying the mold, which certainly defeats the whole purpose of the process.

The elevation view of the generator below shows the construction further along that in the last photo. Much of the side detail has been added, but there is stil more to come. You can begin to get a sense of what an involved model this load is in it's own right.

This bottom view below provides another perspective on the generator construction and the amount of hand assembly and soldering that is required. All things considered, the pricing for this 'model' is extremely reasonable!

This end view shows the largest end cap in place on the generator structure. There are other cast details that will be installed in the remaining openings

6/18/11 - Although the photo below is a bit dated at this point and the two production samples are nearly complete at this point, the photo does show the size relationship of the load to the carbody of the FD-2. There have been many corrections and improvements to both flat car versions and subsequent photos will highlight the changes. Every aspect of the models have been upgraded, from the detail on the underside of the trucks and the side frames to the carbody deck detail. Knowledgeable modelers will be amazed at the difference between our original samples and the final production models. The Westinghouse generator load is being assembled from more than 60 parts, some are fabricated and some are castings. In the background you can see the parts for the FW-1 stamping machine load prior to final assembly. Stay tuned!

5/24/11 - Although I am behind as usual with paperwork, great progress is being made on this project. The production sample models are being finished as of this writing and the first load sample models are also being completed. For reservation holders, the overdue order confirmations have been sent out along with the promised information regarding the loads for the flat cars. The confirmations were delayed as we worked through the process of deciding how the loads would be developed and built, that information had been promised with the confirmations. While the flat car models stand on their own as unique and substantial models, the availability of appropriate loads built to the same standards as the cars complete the concept and add in value to the cars far beyond their ultimate cost. The information regarding the loads has been added to the Download page for this project site. The flat car sample models I have been showing for quite some time have received a great response, if for no other reason, their size is impressive. With the construction modifications, changes and corrections that have been integrated into the production models, the project rises to a whole new level. The deck detail has been completely redone, all of the construction seam detail has been reworked and even the trucks have been completely redesigned adding more detail. The overall affect is stunning by comparison to where we started. To explain a bit further on the development of the flat car loads, I had mentioned at the outset that I would be looking at a number of different approaches for the construction. That in fact was the case, I considered several different rapid prototyping techniques for doing the part patterns, I considered producing the complete models using rapid prototyping and I also looked at reproducing parts in resin using traditional master patterns. This whole effort was intended to provide finely detailed load models commensurate with the quality of the flat cars and do so at a price that would be reasonable. After all was considered, the decision was made to revert to the traditional techniques and to build the load models from brass and to offer them at a price that minimally covers the costs involved in their development and production. The 'flats' will be beautiful models, but with their brass loads, they will be extraordinary. 3/22/11 - Just a brief update to advise all that have sent in reservations, that your confirmation letters are being processed now and will be in the mail shortly. Included with the confirmation letter will be information regarding the loads for both versions of the flat cars. 3/05/11 - Considerable effort has been expended on trying to determine the best approach for producing the loads for our two flat cars. Early on I had mentioned that I was considering using a combination of materials to try and keep the cost factor as low as possible and also to keep the weight factor at an appropriate level. Most all of the feedback that I have received has expressed a common opinion that the loads should be comparable in quality and detail to the cars themselves, that is very understandable. In working through the possibilities thus far, the cost factor will seemingly be higher to employ resin technology and there is concern about the quality of detail and surface finish due to some of the characteristics of the generator load in particular. From this point on, I will be concentrating on making brass models of our loads as cost effective as possible. I will be communicating with all of you that have reserved models directly as soon as I have a bit more information to offer. It is a certainty that I do not want the loads to detract from what will be very exciting and impressive models, the loads need to be real enhancements to what has been accomplished with the cars. 2/22/11 - Just a brief reminder to a number of people that have called expressing interest in ordering one of our PRR flat cars and that have requested that I hold one for them. I can not hold an unpaid reservation indefinitely, there are only 100 units being produced and they are going quickly. I mention this so that hopefully those individuals that have called can avoid disappointment by following up too late with an actual paid reservation. If questions remain, please get in touch directly to have your questions answered. 2/15/11 - Shown below are CAD images of the FW-1 (upper) and FD-2 (lower) flat cars with their intended loads in place. The FW-1 load makes for a very interesting arrangement with the beams and wooden shoring used to hold it in place during transit. The width of the load is almost as wide as the well opening in the flat car. The carbody of the FW-1 was originally built to transport this load, a cast steel frame for a very large stamping machine.

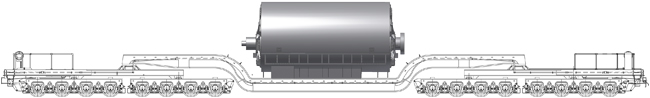

As described previously, the typical load for the FD-2 was a Westinghouse turbo generator, although it was used for other miscellaneous loads on numerous occasions. The two loads pictured were very different in nature, but both weighed in at approximately 500,000 pounds each.

2/08/11 - There have been a couple inquiries regarding the trucks for our 'flats', considering that we are using our new scale wheels. In addition to the scale wheels, the truck frames and bolsters are in fact scale in width. 2/06/11 - Just a brief update to say thank you to all of you that have already reserved your FD-2 and/or FW-1 flat cars! The rate of sale for this project is the fastest I have experienced to date and that is gratifying. Confirmation letters will begin going out very soon. I am continuing to work on the issue of loads for the cars and it may be a situation of turning back to brass construction to produce them. I hope to have more information very soon regarding loads. I have had a couple of inquiries about when painted samples of this project would be available to see; considering how far along the production is, I probably will not bother with painted samples which will only add to the production time and expense. I anticipate taking the first production models to use for photography and any shows that may occur before the production is delivered to the states this Summer. 1/25/1 - Based on my visit to Korea in the last several days, I can tell you that our rolling stock projects are back at full speed ahead. The trucks for the 'flats' are currently being finished after waiting for a massive supply of ball-bearings. The projection for completion of this project is approximately four months at this point. Shown below is a rendered view of the load 'model' for the FD-2 flat car. This load is the most often seen on the FD-2 and it is a Westinghouse turbo generator. This is a pretty clear indication that we are paying as much attention to the loads for the cars as we are the cars themselves. The CAD model shown was created by Nick Seman of Middle Division fame, purveyor of many things 'Pennsy' and a regular contributor on our PRR projects.

1/23/11 - My personal impression has been that the Penn Central versions of our FD-2 and FW-1 could potentially be the most attractive versions of this project that we'll produce. With that in mind, it's not too surprising that I have already received several orders for these two versions. From the outset of the project I have been trying to find a photo of the FD-2 in service during the PC years, luckily I have just located a photo of the FD-2 in full Penn Central dress. The photo has been added to the Prototype Photos page of this project site. Another photo has also been added of the FD-2 in late 'Pennsy' service with what is an atypical load for the FD-2. The most common loads were Westinghouse turbo generators, the added photo shows a massive transformer. As new and interesting photos are located of the prototypes in service, I will continue to add them for modeling reference. 1/14/11 - A further update regarding reservations for this project. Now that the mailing is complete, I have posted the order form on the project download page so it is available for download. I have had a number of requests from our international customers requesting an electronic version of the form to save time and insure that they can place their orders on a timely basis. An ordering preference will still be given to existing customers for approximately two weeks to allow time to respond to the offering. If new customers submit an order it will be held until the preference period has elapsed, if the project should become fully reserved in the interim, reservations that we can not accepted will be returned. All existing customers should receive the offering by postal mail as should anyone that has expressed interest as a new customer, new customer mailings will arrive slightly later. 1/11/11 - The first batch of reservation offering have gone in the mail as of today and the balance will be sent by weeks end. I will also be posting the reservation form on the web site shortly, but will still hold a preference for existing customers until they have had a chance to respond. It is pretty certain that the demand will out strip the supply, so do not delay with your response if this project is of interest. Many thanks to all for your patience! 1/01/11 - There has been a great deal of concern from existing and new customers alike that they would miss out on this project, because they had not received the offering materials. All of the printing for the offering was completed before Christmas, but I felt that it would be best not to do the mailing prior to the holiday. The offering materials will go out to existing customers first, which is the usual practice, immediately following the holiday season and to newly interested modelers approximately two weeks later. If you are an existing customer and the holidays have left you financially drained as a result of your generosity, please let me know and accommodations will be made so that no one is left in the lurch as a result of my less than favorable timing. A big thank you to everyone that has expressed interest in this project and waited patiently for the reservations to start. 11/10/10 - I just obtained a copy of an interesting photo showing the FD-2 undergoing load testing using slabs of steel totaling 501,960 pounds. This weight total is just shy of the rated capacity for the car. I have also posted a short series of photos showing the FD-2 being loaded with it's first actual load, you can view these photos on the Prototype Photos page. Final preparations are also nearly complete to start the reservation process for this project.

10/13/10 - I am finally about ready to start the reservation process on this project, it has taken a bit to get caught up on a number of fronts before it was logical to move forward with this new project. I have posted the project brochure to the Download page and the order form will be posted once it has been sent out to all existing customers. I will update further once the 'paper' is in the mail. Many thanks to all for your patience, the demand has been extreme and everyone has been anxious, I apologize for keeping everyone waiting! 4/28/10 - Although our flat cars are already in production, I have been holding off on starting the reservation process while our 'loads' have been under development. The difficulty with doing the loads has been producing items of appropriate quality without having to charge a significant price in addition to the cost of the cars. I feel comfortable now that we have the process under control and that we'll be delivering loads that are fully compatible with our FD-2 and FW-1 'flats'. The reservation process will begin as soon as the mailing is assembled and ready to go. The production should be complete late this summer. I know that many of you have been extremely anxious about this project and I appreciate your patience while we have been working to get 'things' right! The entire production will be only 100 pieces divided between all the versions so do not delay in responding to the reservation information. 1/20/10 - Additional prototype photos have been posted to this project site showing additional 'load' photos and also alternate paint schemes for the flat cars themselves. We have accumulated a nice file of reference photos that document the usage and paint schemes over the years, but many of the photos are not of great quality, so I have chosen to post only the best or them for your reference. Although I have confirmed what we needed to know, the search continues for interesting 'shots' related to these cars, if you can help please get in touch. As previously mentioned, the development of loads for the FD-2 and FW-1 flat cars is underway. The photo below shows an 'end cap' for the generator load on an FD-2 flat car. The most common loads for the FD-2 are large Westinghouse generators or turbines for electrical power plants. If you refer to the prototype photos shown elsewhere in this project site you will see how this sample part relates to the actual prototype load. Work continues to develop the best approach for building our loads so that we achieve maximum detail with minimum weight and also keep the pricing reasonable. This first parts were created by Harry Hieke at Everything O Scale. Additional photos will be posted as the development continues. I know that many of you have been waiting to get your order in, be advised that I will get the process started as soon as possible at this point. I do not want anyone that has been waiting to miss out due to the delay in getting started.

12/09/09 - Our project update needs to catch up with the actual status of our FW-1/FD-2 project. Not only has our work resumed as previously reported, all of the corrections have been completed for both versions of this project. Significant upgrades have been made to the truck assemblies in terms of detail and the overall level of detail has been improved in terms of the construction detail (ie...weld lines, sheet seams, etc). The handrails have been changed from being one complete cast brass structure to being fabricated from stainless with individual components, this allows for stronger and more accurately aligned detail. Although we have yet to start the reservation process for this project, the production of parts is underway. I would like to start the reservations as soon as possible, because I know that so many people have been patiently waiting, but a decision needs to be made whether it should start before or after the Christmas season as this point. The development of 'loads' for the two 'flats' has begun and photos of the first parts will be posted very soon. The loads that are being developed will be sold separately from the flat-car models themselves and will be very reasonably priced. The load models will use a combination of brass and resin to keep the weight manageable while providing complete detail commensurate with that of the flat-car models themselves. 6/16/09 - Work on our 'BIG' flat car project has resumed and we will be moving towards starting the reservation process shortly. A full series of detail photos has been shot and is currently being processed for posting on the web, I expect that the photos will be up during our visit to the O Scale National Convention over the next few days. We have also arranged for the fabrication of prototypical loads for our flats and they will be sold separately from the cars themselves. The sample loads will hopefully be started very soon so we can provide photos. We are getting back up to speed on all of the projects that were dormant for several months, I do appreciate your patience during this time. 10/01/08 - We have posted the first of the prototype images of the FD-2 and FW-1 flat cars also including loads. We will be adding to the images, but they are few and far between, particularly the FW-1 photos. The photos of the FW-1 that we have were provided by Mr. Michael Schafer who has been researching the subject for a number of years, our thanks to Michael for his kind offer to let us use his photos. 9/28/08 - We are getting close to starting the reservation process on this project, if you are not a current customer and have not advised us of your interest, please do so very soon so you will not be left out. This project promises to sell out very quickly! More detail photos of the two sample model versions will be posted shortly as well as some interesting photos of the prototypes in service which are very difficult to some by. 1/28/08 - We have just posted on this projects home-page, the first photo of the sample models just completed by our rolling stock builder, Mr. Sin. This project is running ahead of schedule in large part due to the dedication and hard work of Mr. Sin and his team. The models will be shown at the Nurnberg Toy Fair early next month in Germany and they are on the way to our shop now. Additional photos will be posted at the earliest opportunity and they will also be included in the forthcoming printed update that will be mailed to everyone that is a customer or on our mailing list. We are now working on prototypical loads for each 'flat' the will help demonstrate the significant role they played during their service. Regarding production schedule; our next rolling stock project in production are our PRR N5/N5b cabin cars, followed by our Chesapeake & Ohio steel cabooses and then our FW-1/FD-2 'flats' will go into production a bit later this year. 11/01/07 - The initial design has been completed for both version of this project, the FW-1 and the FD-2. As we proceed with the sample construction, we are also working on a suitable load to be carried by these 'flats'. |